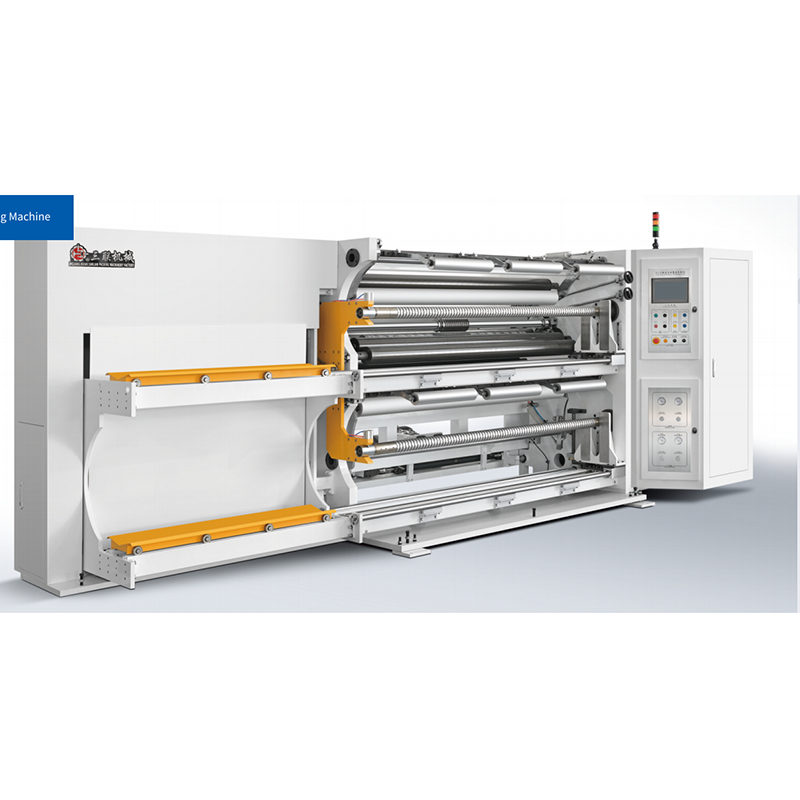

High-Quality Slitting Rewinding Services for Your Business

By:Admin

In the realm of slitting and rewinding, one company that stands out for its excellent quality and reliable performance is {}. With years of experience in the industry, {} has made a name for itself as a leading provider of slitting and rewinding solutions.

Established in [year], {} has consistently delivered top-notch products and services to its customers, catering to a wide range of industries. The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the curve and provide cutting-edge solutions to its clients.

{} offers a comprehensive range of slitting and rewinding machinery, designed to meet the specific needs of its customers. Whether it's for custom slitting, precision rewinding, or high-speed production, {} has the expertise and equipment to deliver tailored solutions.

One of the key strengths of {} is its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery. This allows the company to produce high-quality slitting and rewinding equipment that meets the highest industry standards.

Furthermore, {} takes pride in its team of highly skilled and experienced professionals who are dedicated to providing exceptional service to its customers. The company's technical expertise and industry knowledge enable it to offer reliable advice and support to its clients, ensuring that they get the most out of their slitting and rewinding operations.

In addition to its product offerings, {} also provides comprehensive maintenance and support services to its customers. This includes equipment installation, training, and troubleshooting assistance, ensuring that clients can operate their slitting and rewinding machinery with maximum efficiency and effectiveness.

Moreover, {} is committed to sustainability and environmental responsibility, incorporating eco-friendly practices into its manufacturing processes. The company places a strong emphasis on reducing waste and energy consumption, while also developing eco-friendly products that align with the principles of sustainability.

The success of {} in the slitting and rewinding industry can be attributed to its relentless pursuit of excellence and customer satisfaction. The company's unwavering dedication to quality, innovation, and service has earned it a sterling reputation in the market, making it the go-to choice for slitting and rewinding solutions.

Looking to the future, {} continues to strive for growth and development, exploring new technologies and opportunities to further enhance its product offerings and services. Through its commitment to excellence and customer-centric approach, {} is well-positioned to remain a leader in the slitting and rewinding industry for years to come.

In conclusion, slitting and rewinding is a critical process in various industries, and {} is a company that has consistently delivered top-notch solutions to meet the needs of its customers. With its focus on quality, innovation, and customer satisfaction, {} has established itself as a trusted and reliable partner in the slitting and rewinding industry.

Company News & Blog

Discover the Latest Non Woven Bag Machine Technology for Sustainable Packaging

The demand for eco-friendly and sustainable packaging solutions continues to rise as consumers become more environmentally conscious. In response to this growing market trend, (company name) has introduced a state-of-the-art Non Woven Bag Machine that is designed to produce high-quality, durable, and reusable non-woven bags.The (company name) Non Woven Bag Machine is equipped with advanced technology and automated systems to ensure efficient and precise production. This machine is capable of creating non-woven bags in a variety of sizes, styles, and designs to meet the needs of different customers. Whether it’s a small tote bag for groceries or a large carry-all for shopping, the Non Woven Bag Machine can manufacture a wide range of eco-friendly bags to cater to various requirements.The non-woven bags produced by this machine are made from polypropylene material, which is known for its strength, durability, and recyclability. Unlike single-use plastic bags, non-woven bags can be reused multiple times, reducing the amount of plastic waste in the environment. With the (company name) Non Woven Bag Machine, businesses can contribute to the global effort to reduce plastic pollution by offering sustainable packaging solutions to their customers.In addition to its environmental benefits, non-woven bags also provide a versatile and cost-effective packaging solution for businesses. These bags can be customized with different prints, colors, and handles to create attractive and functional packaging that promotes brand awareness. Whether it’s a promotional event, trade show, or retail store, non-woven bags are an effective marketing tool that can enhance the visibility and image of a brand.The introduction of the Non Woven Bag Machine reaffirms (company name) commitment to sustainability and innovation in the packaging industry. By investing in advanced technology and production capabilities, (company name) aims to support businesses in their transition towards more sustainable packaging solutions. The Non Woven Bag Machine is a testament to (company name) dedication to delivering high-quality and eco-friendly products that meet the evolving needs of the market.The Non Woven Bag Machine is just one of the many initiatives that (company name) has undertaken to promote sustainability and environmental responsibility. The company’s commitment to corporate social responsibility is reflected in its efforts to reduce energy consumption, minimize waste, and support local communities. By integrating sustainable practices into its operations, (company name) strives to set an example for the industry and inspire others to embrace environmentally-friendly solutions.In conclusion, the introduction of the Non Woven Bag Machine by (company name) represents a significant milestone in the company’s journey towards sustainability and innovation. The machine’s capability to produce high-quality, reusable non-woven bags aligns with the growing demand for eco-friendly packaging solutions in the market. Through this initiative, (company name) aims to support businesses in their transition towards more sustainable packaging options and contribute to the global effort to reduce plastic waste. As the company continues to expand its portfolio of sustainable products, it remains committed to making a positive impact on the environment and the communities it serves.

High-Quality Aluminum Slitter: The Latest Innovation in Metal Processing

Aluminum Slitter: Revolutionizing the Aluminum IndustryIn a world of constant innovation and technological advancement, the aluminum industry is no exception. With the demand for high-quality aluminum products on the rise, the need for efficient and precise aluminum slitting technology has become more critical than ever. This is where the cutting-edge Aluminum Slitter, offered by {}, comes into play.{Company Name} is a renowned leader in providing advanced solutions for the aluminum industry. With a strong commitment to innovation and customer satisfaction, the company has established itself as a trusted partner for aluminum manufacturers and processors around the world. The Aluminum Slitter is a testament to their dedication to providing state-of-the-art equipment that meets the evolving needs of the industry.The Aluminum Slitter is a sophisticated piece of machinery that is designed to improve the efficiency and quality of aluminum slitting processes. It boasts a range of features that set it apart from traditional slitting equipment, making it a game-changer for aluminum manufacturers. With its advanced technology and precision engineering, the Aluminum Slitter offers unmatched performance and reliability, allowing manufacturers to meet the demands of a competitive market with ease.One of the key advantages of the Aluminum Slitter is its ability to achieve tight tolerances and consistent results, ensuring that the slit aluminum products meet the highest quality standards. This level of precision is essential for applications where tight tolerances are crucial, such as in the automotive, aerospace, and construction industries. With the Aluminum Slitter, manufacturers can confidently produce aluminum products that meet the most stringent requirements, giving them a competitive edge in the market.The Aluminum Slitter is also engineered for maximum efficiency, with features that streamline the slitting process and minimize downtime. Its high-speed operation and quick changeover capabilities enable manufacturers to increase their productivity and respond to changing production requirements with minimal disruption. This level of agility is essential in today's fast-paced manufacturing environment, where flexibility and responsiveness are key to staying ahead of the competition.In addition to its unparalleled performance, the Aluminum Slitter is designed with operator safety and ease of use in mind. Its intuitive controls and ergonomic design make it user-friendly, ensuring that operators can work efficiently and with confidence. Furthermore, the Aluminum Slitter is equipped with advanced safety features to protect personnel and prevent accidents, supporting a secure and productive work environment.{Company Name} takes pride in offering comprehensive support for the Aluminum Slitter, including installation, training, and ongoing maintenance services. Their team of experts is dedicated to ensuring that customers can maximize the potential of the equipment, providing technical assistance and guidance every step of the way. This commitment to customer satisfaction sets {Company Name} apart as a trusted partner for aluminum manufacturers seeking reliable solutions for their production needs.As the aluminum industry continues to evolve, the demand for advanced slitting technology will only grow. The Aluminum Slitter stands at the forefront of this evolution, offering a solution that combines precision, efficiency, and reliability in one powerful package. With its innovative design and proven performance, the Aluminum Slitter is shaping the future of aluminum processing, empowering manufacturers to deliver superior products in a competitive market.

Efficient Slitting Rewinding Services You Can Trust

Slitting Rewinding, a crucial process in the manufacturing industry, plays a vital role in converting large rolls of material into smaller, more manageable rolls. This process is commonly used in the production of various products including paper, film, foil, and nonwovens. It involves cutting the material into the desired width and then rewinding it onto new cores. The precision and accuracy of the slitting and rewinding process are crucial to ensuring the quality and consistency of the final product.With the growing demand for high-quality slitting and rewinding services, companies are constantly seeking innovative solutions to enhance their production capabilities. One company that has been at the forefront of providing state-of-the-art slitting and rewinding services is {}. With a strong focus on precision engineering and advanced technology, the company has established itself as a leader in the industry.The slitting and rewinding process offered by {} is a combination of cutting-edge technology, skilled craftsmanship, and strict quality control measures. This ensures that the company is able to meet the diverse needs of its customers while maintaining the highest standards of quality. The company's state-of-the-art facilities and dedicated team of professionals enable it to handle a wide range of materials, including paper, film, foil, and nonwovens, with precision and efficiency.One of the key factors that sets {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This allows {} to offer cutting-edge solutions that meet the ever-evolving needs of its customers. Whether it's custom slitting and rewinding services or the development of new processes, {} is dedicated to delivering solutions that exceed customer expectations.In addition to its technological prowess, {} places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and deliver tailored solutions that meet their needs. By fostering strong relationships with its customers, {} has earned a reputation for reliability, flexibility, and exceptional service.Furthermore, {} is also committed to sustainability and environmental responsibility. The company adheres to strict environmental standards and employs eco-friendly practices in its manufacturing processes. This not only minimizes the company's impact on the environment but also ensures that its customers receive products that are manufactured in a sustainable and responsible manner.As the demand for high-quality slitting and rewinding services continues to grow, {} remains at the forefront of the industry, providing cutting-edge solutions that meet the evolving needs of its customers. With its unwavering commitment to precision, quality, innovation, and customer satisfaction, {} is poised to continue its leadership in the slitting and rewinding industry for years to come.

High-Quality Roll Slitter Rewinder for Efficient Material Processing

Roll Slitter Rewinder, a key product offered by a leading manufacturing company, has revolutionized the industry with its advanced features and cutting-edge technology. This precision machine has redefined the process of slitting and rewinding materials, making it more efficient and accurate than ever before. With its state-of-the-art design and unmatched performance, Roll Slitter Rewinder has set a new standard for excellence in the field.The company, which specializes in the production of industrial machinery, has been at the forefront of innovation for over two decades. With a team of highly skilled engineers and technicians, they have consistently delivered superior quality equipment to meet the diverse needs of their clients. The Roll Slitter Rewinder is a testament to their commitment to excellence and their dedication to pushing the boundaries of technological advancement.One of the key features of the Roll Slitter Rewinder is its precision cutting capabilities. With its advanced cutting mechanism, this machine is able to slit materials with unparalleled accuracy, ensuring clean and precise cuts every time. This level of precision is essential for industries that require exact specifications for their materials, such as the packaging and labeling industry. The Roll Slitter Rewinder has proven to be a game changer in these sectors, allowing companies to meet their production needs with unmatched precision and efficiency.In addition to its cutting capabilities, the Roll Slitter Rewinder also boasts a high-speed rewinding function. This allows for seamless and efficient rewinding of materials, reducing downtime and increasing overall productivity. With its customizable settings and user-friendly interface, operators can easily set the machine to meet their specific rewinding requirements, further enhancing the efficiency and versatility of the Roll Slitter Rewinder.Furthermore, the Roll Slitter Rewinder has been designed with durability and longevity in mind. Constructed with high-quality materials and built to withstand the rigors of heavy-duty industrial use, this machine is a reliable and long-lasting investment for any company. Its low maintenance requirements and robust construction ensure that it will continue to deliver exceptional performance for years to come, making it a cost-effective solution for businesses of all sizes.The company behind the Roll Slitter Rewinder takes great pride in providing comprehensive support to their clients. From initial consultation to installation and ongoing maintenance, their team of experts is dedicated to ensuring that every customer receives the highest level of service and satisfaction. With a focus on understanding the unique needs of each client, they work closely with them to deliver tailored solutions that meet and exceed their expectations.As the industry continues to evolve, the Roll Slitter Rewinder remains at the forefront of innovation. The company is constantly researching and developing new technologies to further enhance the capabilities of this machine, ensuring that it remains a market leader in the field of slitting and rewinding equipment. With a relentless commitment to excellence and a passion for continuous improvement, the company is poised to continue setting new standards for performance and reliability in the industry.In conclusion, the Roll Slitter Rewinder is a groundbreaking product that has redefined the industry with its advanced features and cutting-edge technology. Backed by a company known for its unwavering commitment to excellence and customer satisfaction, this precision machine has set a new standard for efficiency, accuracy, and reliability. As the company continues to push the boundaries of innovation, the Roll Slitter Rewinder is poised to remain a leader in the field for years to come.

High-Quality Foil Slitting Machines: Everything You Need to Know

Foil Slitting Machine Revolutionizes the Packaging IndustryIn the fast-paced world of packaging, efficiency, and precision are key elements to success. With the introduction of the latest Foil Slitting Machine by a leading industry player, packaging companies can now experience a new level of productivity and accuracy in their operations.The Foil Slitting Machine, designed and manufactured by the innovative team at {}, has quickly become the talk of the town in the packaging industry. It is designed to meet the growing demand for high-quality foil products used in various packaging applications such as food, pharmaceuticals, and industrial products. The machine offers a perfect solution for companies looking to streamline their operations and enhance the quality of their products.With its state-of-the-art technology and advanced features, the Foil Slitting Machine is set to revolutionize the way foil products are processed and manufactured. Its precision cutting capabilities ensure a uniform and consistent output, reducing material waste and boosting overall efficiency. The machine is also equipped with automation features that minimize the need for manual intervention, further increasing productivity and reducing the risk of human error.One of the key highlights of the Foil Slitting Machine is its versatility in handling a wide range of foil materials. Whether it is aluminum, copper, or any other metal foil, the machine can effortlessly process and slit them to the desired specifications. This flexibility makes it an ideal choice for packaging companies dealing with diverse product lines and customized packaging requirements.In addition to its cutting-edge technology, the Foil Slitting Machine is also designed with user convenience in mind. Its user-friendly interface and intuitive controls make it easy for operators to set up and adjust the machine for different production runs. This not only saves time but also allows for quick changeovers between different foil materials and thicknesses.Furthermore, the Foil Slitting Machine is built to meet the highest standards of quality and safety. It undergoes rigorous testing and quality checks to ensure reliable performance and durability in a demanding production environment. This commitment to excellence is a testament to the company's dedication to providing top-of-the-line machinery for the packaging industry.With the unveiling of the Foil Slitting Machine, {} has once again proven its reputation as a leading innovator in the packaging machinery market. The company's unwavering commitment to research and development has resulted in a product that not only meets the current needs of the industry but also sets a new standard for future advancements.As the demand for high-quality foil products continues to rise, the Foil Slitting Machine is set to play a crucial role in helping packaging companies stay ahead of the competition. Its ability to deliver precision, efficiency, and versatility makes it a game-changer in the packaging industry, offering companies a competitive edge in delivering superior products to their customers.In conclusion, the introduction of the Foil Slitting Machine marks a significant milestone in the packaging industry. With its cutting-edge technology, versatility, and user-friendly design, it is set to pave the way for a new era of efficiency and excellence in foil processing and manufacturing. As packaging companies embrace this groundbreaking innovation, they can look forward to redefining their production capabilities and delivering unmatched quality in their packaging solutions.

High-Quality Non Woven Bag Making Machine for Efficient Production

[Company Introduction] A leading manufacturer of non woven bag making machines, {Company Name} has been at the forefront of the non woven packaging industry for over a decade. With a strong emphasis on innovation, quality, and customer satisfaction, the company has earned a stellar reputation for delivering cutting-edge solutions to its global customer base. {Company Name}'s state-of-the-art manufacturing facilities and dedicated R&D team enable the company to consistently develop high-performance machinery that meets the evolving needs of the non woven bag industry.[News Content]In recent years, the global push towards sustainability and environmental consciousness has significantly increased the demand for non woven bags as an eco-friendly alternative to traditional plastic bags. As a result, the non woven bag making industry has witnessed rapid growth, prompting manufacturers to invest in advanced machinery to meet the rising production demands.Recognizing the need for efficient and high-speed non woven bag making equipment, {Company Name} has announced the launch of its latest innovation – the {Model Name} Non Woven Bag Making Machine. This cutting-edge machine is designed to revolutionize the production process of non woven bags, offering an unmatched combination of speed, precision, and versatility.Featuring a modular and ergonomic design, the {Model Name} Non Woven Bag Making Machine is engineered to optimize production efficiency while minimizing downtime. Equipped with advanced automation technology, the machine boasts a user-friendly interface, allowing operators to easily set parameters and monitor the production process with precision. Additionally, the machine's high-speed capabilities enable it to produce a wide range of non woven bag designs, including flat bags, D-cut bags, box bags, and more, catering to the diverse needs of the packaging industry.One of the key highlights of the {Model Name} Non Woven Bag Making Machine is its ability to handle various non woven fabric types, including PP non woven, PPE non woven, and more. This flexibility allows manufacturers to utilize different materials based on the specific requirements of their customers, further enhancing the machine's value proposition.Furthermore, {Company Name} has integrated innovative technology to ensure that the {Model Name} Non Woven Bag Making Machine delivers consistent and precise sealing, cutting, and printing processes. This attention to detail reflects the company's commitment to empowering its customers with reliable and high-quality machinery that sets new industry benchmarks.In addition to its technical prowess, the {Model Name} Non Woven Bag Making Machine is also designed with a focus on sustainability. By minimizing material wastage and energy consumption, the machine aligns with the global efforts to reduce the environmental impact of manufacturing processes, making it an ideal choice for eco-conscious businesses.With its introduction of the {Model Name} Non Woven Bag Making Machine, {Company Name} aims to further solidify its position as a leading provider of advanced solutions for the non woven packaging industry. The company's dedication to pushing the boundaries of innovation and exceeding customer expectations continues to drive its success in serving the evolving needs of the global market.Ultimately, the {Model Name} Non Woven Bag Making Machine represents a significant leap forward in non woven bag production technology, offering manufacturers unmatched performance, flexibility, and sustainability. As the demand for eco-friendly packaging solutions continues to grow, {Company Name} remains steadfast in its commitment to empowering its customers with cutting-edge machinery that enables them to thrive in a rapidly changing market landscape.

Highly Efficient Automatic Slitting Machine for Industrial Use

Automatic Slitting Machine Revolutionizes the Manufacturing IndustryIn today's fast-paced and demanding manufacturing industry, the need for efficient and reliable equipment is more important than ever. One company leading the way in this regard is {Company Name}, a renowned manufacturer of high-quality industrial machinery. Recently, {Company Name} has introduced the latest innovation in their product lineup, the Automatic Slitting Machine, which is set to revolutionize the way materials are processed and transformed in the manufacturing sector.The Automatic Slitting Machine is designed to meet the growing demand for precision, speed, and flexibility in material processing. It is equipped with state-of-the-art technology and a user-friendly interface, making it easy to operate and highly efficient. The machine is capable of slitting a wide range of materials, including paper, plastic, metal, and non-woven fabrics, ensuring that manufacturers can easily adapt to changing production requirements.One of the key features of the Automatic Slitting Machine is its ability to perform high-speed and high-precision slitting, allowing for increased productivity and reduced material waste. This is particularly important in industries such as packaging, printing, and textile manufacturing, where the ability to accurately process materials is crucial to meeting customer demands and market trends. With the Automatic Slitting Machine, manufacturers can expect improved product quality and reduced production costs, giving them a competitive edge in the market.Another notable feature of the Automatic Slitting Machine is its flexibility in handling various material widths and thicknesses. This versatility allows manufacturers to easily switch between different materials and sizes without the need for extensive retooling or adjustments, saving time and resources in the production process. Additionally, the machine's automated setup and cutting parameters further enhance its efficiency and adaptability, ensuring consistent and precise results with every use.{Company Name} has a strong reputation for delivering reliable and long-lasting industrial equipment, and the Automatic Slitting Machine is no exception. The machine is built to withstand the rigors of industrial use, with durable components and a robust construction that ensures years of trouble-free operation. Moreover, {Company Name} provides comprehensive technical support and maintenance services, ensuring that customers can maximize the performance and lifespan of their investment.The introduction of the Automatic Slitting Machine reflects {Company Name}'s commitment to innovation and customer satisfaction. By continually investing in research and development, {Company Name} strives to stay at the forefront of technological advancements in the manufacturing industry, offering cutting-edge solutions that address the evolving needs of their customers.The Automatic Slitting Machine is the latest addition to {Company Name}'s diverse product range, which includes a wide variety of industrial machinery such as laminating machines, die-cutting machines, and printing equipment. With a strong focus on quality, reliability, and performance, {Company Name} has earned the trust and respect of manufacturers worldwide, establishing itself as a leading provider of industrial solutions.In conclusion, the introduction of the Automatic Slitting Machine by {Company Name} marks a significant advancement in the manufacturing industry, providing manufacturers with a powerful tool to enhance their production capabilities. With its advanced features, precision performance, and robust construction, the Automatic Slitting Machine is poised to set new standards in material processing, offering unmatched efficiency and versatility for a wide range of applications. As the demand for high-quality and high-speed production continues to grow, {Company Name} remains dedicated to providing innovative solutions that empower manufacturers to thrive in today's competitive market.

High-Quality and Efficient Label Slitter Rewinder Machine for Your Business

A leading manufacturer of converting equipment, [Company Name], has recently launched a new Label Slitter Rewinder Machine, further solidifying its position as a key player in the industry. With its innovative technology and precision engineering, the Label Slitter Rewinder Machine is set to revolutionize the way labels are produced, offering enhanced efficiency and quality.The Label Slitter Rewinder Machine is designed to meet the growing demand for high-speed and high-precision label production. It is equipped with advanced features that allow for precise slitting, rewinding, and inspection of a wide range of label materials, including paper, film, and laminates. This versatility makes it an ideal solution for label manufacturers looking to streamline their production processes and meet the diverse needs of their customers.One of the key highlights of the Label Slitter Rewinder Machine is its cutting-edge slitting technology, which ensures clean and accurate cuts, even at high speeds. This is made possible by the machine's precision-engineered slitting blades and advanced control system, which work in tandem to deliver consistent results with minimal waste. Additionally, the machine also features an intuitive inspection system that detects and flags any defects in the label material, allowing for quick and efficient quality control.In addition to its cutting-edge technology, the Label Slitter Rewinder Machine is also designed with user-friendly features that enhance its overall efficiency and ease of use. The machine is equipped with a user-friendly interface that allows for easy setup and operation, as well as quick changeovers between different label materials and sizes. This not only reduces downtime but also improves overall productivity, making it a valuable addition to any label production facility.Furthermore, the Label Slitter Rewinder Machine is built with durability and reliability in mind, ensuring long-term performance and minimal maintenance requirements. Its robust construction and high-quality components make it capable of handling heavy-duty production demands, day in and day out, while maintaining consistent performance and accuracy.As a leading manufacturer of converting equipment, [Company Name] is committed to delivering cutting-edge solutions that meet the evolving needs of the label industry. The launch of the Label Slitter Rewinder Machine is a testament to this commitment, and it further solidifies the company's position as a trusted partner for label manufacturers worldwide.With its innovative technology, precision engineering, and user-friendly design, the Label Slitter Rewinder Machine is poised to set new standards for label production, delivering unmatched efficiency and quality. Whether it's high-speed slitting, precise rewinding, or reliable quality control, this new machine is set to redefine the label production process for years to come.In conclusion, the launch of the Label Slitter Rewinder Machine marks an exciting development for the label industry, offering label manufacturers a game-changing solution that addresses their evolving needs. With its advanced technology, user-friendly design, and robust construction, this new machine is set to drive efficiency, productivity, and quality in label production, further solidifying [Company Name]'s position as a leader in the converting equipment industry.

Efficient Steel Slitting Line for Precision Cutting and Processing

Steel Slitting Line Enhances Efficiency and Productivity in Metal ProcessingA reputable steel processing company is proud to announce the installation of a state-of-the-art Steel Slitting Line from {brand name}. This advanced machinery is set to revolutionize the way the company processes steel and other metal materials, offering a wide range of benefits including improved efficiency, enhanced productivity, and superior quality output.The Steel Slitting Line is designed to accurately and precisely cut and slit coils of steel into narrower strips, allowing for greater flexibility in meeting the specific needs of customers. This means that the company can now offer a wider range of steel products in varying widths, meeting the demands of different industries such as automotive, construction, and manufacturing.One of the key features of the Steel Slitting Line is its high-speed cutting capabilities, which significantly reduces processing time and turnaround for orders. This means that the company can now fulfill orders in a much shorter timeframe, allowing for faster delivery and improved customer satisfaction.In addition to speed, the Steel Slitting Line also offers increased accuracy and consistency in the cutting process. This ensures that the resulting steel strips are of the highest quality, with precise dimensions and clean-cut edges. This is crucial for industries that require strict adherence to specifications and quality standards.Furthermore, the Steel Slitting Line is equipped with advanced automation and control systems, ensuring seamless operation and minimal downtime. This not only improves overall efficiency but also reduces the margin for error, resulting in cost savings and waste reduction.The company prides itself on its commitment to sustainability, and the installation of the Steel Slitting Line aligns with this ethos. By optimizing the cutting and slitting process, the company is able to minimize material wastage and reduce its environmental impact, contributing to a more sustainable and eco-friendly operation.The investment in the Steel Slitting Line is a testament to the company's dedication to staying at the forefront of technological advancements in the steel processing industry. By embracing the latest innovations and technologies, the company aims to remain a leader in the market and continue to provide its customers with the highest quality products and services.In addition to the installation of the Steel Slitting Line, the company is also committed to ongoing training and development for its workforce. This ensures that the team is fully equipped to operate and maintain the new machinery, maximizing its potential and ensuring long-term reliability and performance.The company's management is optimistic about the positive impact that the Steel Slitting Line will have on its operations and overall business growth. They believe that the enhanced efficiency and productivity offered by the new machinery will not only improve the company's competitiveness in the market but also open up new opportunities for expansion and diversification.With the installation of the Steel Slitting Line, the company is poised to elevate its position as a leading provider of high-quality steel products, meeting the evolving needs of its customers and catering to a wide range of industries. The advanced capabilities of this new machinery will undoubtedly set the company apart in a highly competitive market, solidifying its reputation for excellence and innovation.In conclusion, the installation of the Steel Slitting Line marks a significant milestone for the company, ushering in a new era of enhanced efficiency, productivity, and quality in steel processing. This investment underscores the company's commitment to continuous improvement and innovation, ensuring that it remains a trusted and reliable partner for its customers now and in the future.

High quality cotton bag making machine for efficient production

Cotton Bag Making Machine Revolutionizes Packaging IndustryIn the ever-evolving world of packaging and manufacturing, innovations are constantly being made to improve efficiency and sustainability. One such innovation comes in the form of the new Cotton Bag Making Machine by a renowned company in the industry. This groundbreaking machine is set to revolutionize the way cotton bags are produced, providing a sustainable and cost-effective solution for businesses worldwide.The company behind this cutting-edge technology has been a leader in the packaging and manufacturing sector for over two decades. With a strong focus on sustainability and eco-friendly solutions, they have consistently delivered high-quality machinery to meet the evolving needs of the industry. Their dedication to innovation and customer satisfaction has earned them a reputation as a trusted and reliable partner for businesses seeking to improve their packaging processes.The new Cotton Bag Making Machine is a testament to the company's commitment to sustainability. By utilizing this state-of-the-art technology, businesses can now produce high-quality cotton bags with ease and efficiency. The machine is designed to handle various sizes and thickness of cotton fabric, allowing for flexibility in bag production. Additionally, it is equipped with advanced features that ensure precise cutting, stitching, and finishing, resulting in a superior end product.One of the key advantages of this machine is its ability to significantly reduce production costs. By automating the bag-making process, businesses can save on labor expenses while increasing their output. This not only improves overall efficiency but also contributes to a more sustainable and environmentally friendly operation. The use of cotton fabric further enhances the eco-friendly aspect of the machine, as cotton is a renewable and biodegradable material.Furthermore, the Cotton Bag Making Machine aligns with the growing global trend towards sustainable packaging solutions. As consumer awareness of environmental issues continues to rise, businesses are under increasing pressure to minimize their environmental impact. By investing in machinery that enables the production of eco-friendly cotton bags, companies can demonstrate their commitment to sustainability and appeal to environmentally conscious consumers.In addition to its environmental benefits, the new machine also offers a high level of versatility and customization. Businesses can easily adjust the settings to produce bags of different sizes, shapes, and designs, catering to a wide range of packaging needs. This level of flexibility is invaluable for companies looking to differentiate their products and stand out in a competitive market.The company's dedication to customer satisfaction is reflected in the comprehensive support and training they provide for their machinery. With a team of experienced professionals, they offer installation, training, and ongoing technical assistance to ensure that businesses can fully maximize the potential of their Cotton Bag Making Machine. This level of support gives businesses peace of mind, knowing that they have a reliable partner to help them navigate the transition to sustainable packaging solutions.Overall, the launch of the Cotton Bag Making Machine represents a significant step forward in the packaging and manufacturing industry. By providing a sustainable, cost-effective, and versatile solution for producing cotton bags, the company is empowering businesses to embrace eco-friendly practices while enhancing their operational efficiency. As sustainability continues to be a driving force in consumer preferences, this innovative machine is poised to make a substantial impact on the way packaging is approached in the years to come. With its combination of cutting-edge technology and a strong commitment to customer support, the company has once again demonstrated its leadership in delivering sustainable and forward-thinking solutions to the industry.