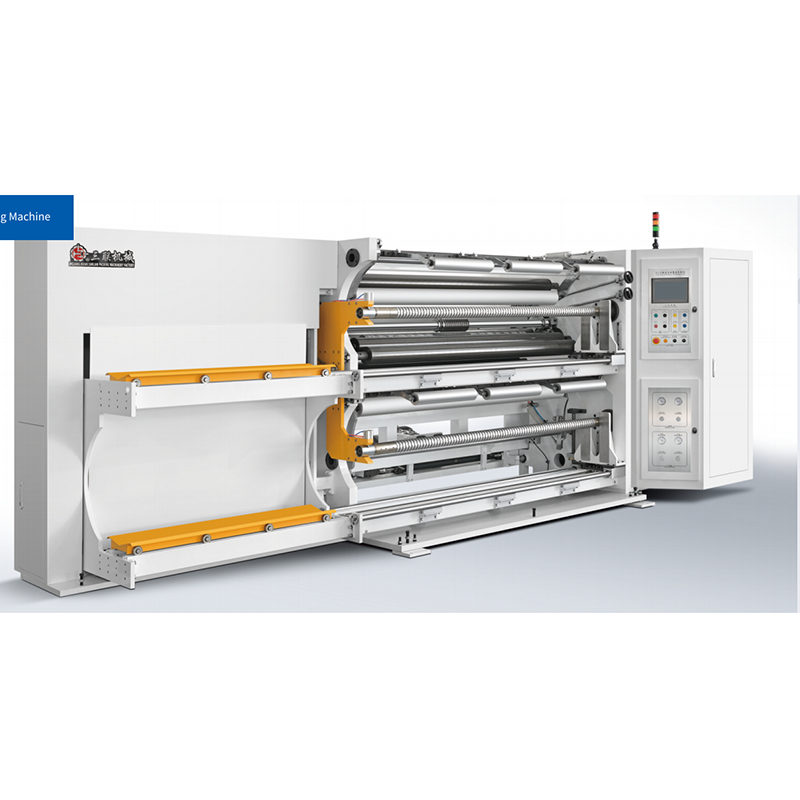

High-Quality Paper Slitting and Rewinding Machine for Efficient Production

By:Admin

The [Company Name] has been at the forefront of innovation in the paper processing industry for over three decades. With a strong focus on research and development, the company has continually introduced cutting-edge machinery that has set new industry standards. The new Paper Slitting And Rewinding Machine is a testament to [Company Name]'s commitment to innovation and excellence.

The new Paper Slitting And Rewinding Machine is designed to meet the evolving needs of the paper processing industry. With a focus on efficiency, precision, and automation, the machine offers a range of advanced features that set it apart from traditional models. The machine is capable of slitting and rewinding a wide range of paper materials with high accuracy and speed, making it ideal for large-scale manufacturing operations.

One of the key features of the new machine is its advanced control system, which allows for precise adjustment of slitting and rewinding parameters. This level of control ensures that the machine can handle various paper materials, including delicate specialty papers, with ease and accuracy. Furthermore, the machine's automated setup and changeover capabilities minimize downtime and increase overall productivity.

The machine also incorporates state-of-the-art safety features to ensure the wellbeing of operators and maintenance personnel. With comprehensive safety interlocks and guarding, the machine adheres to the highest safety standards, providing peace of mind for operators and maintaining a safe working environment.

In addition to its advanced features, the new Paper Slitting And Rewinding Machine is designed with sustainability in mind. The machine's energy-efficient design and minimal material waste make it an environmentally friendly choice for paper processing operations. With a focus on reducing environmental impact, [Company Name] continues to lead the way in sustainable manufacturing practices.

The new machine has already garnered significant interest from paper manufacturers and converters worldwide. Its ability to improve efficiency, accuracy, and safety while minimizing environmental impact has positioned it as a game-changer in the paper processing industry. [Company Name] has already received orders for the new machine from several key industry players, signaling a strong market demand for its innovative features.

In line with [Company Name]'s tradition of providing exceptional after-sales support, the new machine is backed by a comprehensive service and maintenance program. With a global network of service technicians and parts distribution centers, [Company Name] is committed to ensuring that customers can maximize the performance and longevity of their machinery.

With the introduction of the new generation Paper Slitting And Rewinding Machine, [Company Name] has once again established itself as a pioneer in the paper processing industry. As the demand for high-quality, efficient, and sustainable paper processing machinery continues to rise, [Company Name] is well-positioned to meet the needs of manufacturers and converters around the world.

For more information about the new Paper Slitting And Rewinding Machine and other innovative products from [Company Name], visit their website or contact their sales team directly.

Company News & Blog

Top Textile Slitting Machine for Precision Cutting and Finishing

Textile Slitting Machine Revolutionizes Production Process for Garment ManufacturersIn the fast-paced world of garment manufacturing, every second counts. Production efficiency is a top priority for companies looking to stay ahead of the competition, and the use of cutting-edge technology is crucial in achieving this goal.One such piece of technology that is revolutionizing the production process for garment manufacturers is the Textile Slitting Machine. This innovative machine has been developed to meet the increasing demands of the textile industry by providing a high-speed, precision cutting solution for a wide range of fabrics.The Textile Slitting Machine, designed and produced by a leading machinery manufacturer, has gained the attention of garment manufacturers around the world for its ability to significantly improve production efficiency and reduce material waste.With the ability to process a variety of fabrics, including cotton, polyester, and nylon, the machine is versatile enough to meet the needs of different garment manufacturing operations. Its high-speed cutting capabilities allow for rapid processing of fabric rolls, enabling manufacturers to meet tight production deadlines and fulfill customer orders on time.The precision of the Textile Slitting Machine is also a key feature that sets it apart from traditional cutting methods. With advanced technology and cutting-edge engineering, the machine can cut fabrics to extremely precise measurements, ensuring uniformity and consistency in the production process. This level of precision not only improves the quality of the final product but also reduces material waste, ultimately leading to cost savings for manufacturers.Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, allowing for seamless integration into existing production lines. Its automated features further enhance its efficiency, reducing the need for manual labor and streamlining the overall production process.As garment manufacturers continue to seek ways to improve their production processes, the Textile Slitting Machine has emerged as a game-changer in the industry. Its ability to increase production efficiency, reduce material waste, and improve the overall quality of garment production has made it an invaluable asset for companies looking to stay competitive in today's market.In addition to its technical capabilities, the Textile Slitting Machine is backed by a company with a rich history of innovation and excellence in the manufacturing industry. With a strong focus on research and development, this company has consistently delivered cutting-edge solutions to its clients, helping them to optimize their production processes and achieve their business objectives.Driven by a commitment to quality, reliability, and customer satisfaction, the company has earned a reputation as a trusted partner for garment manufacturers seeking advanced machinery solutions. Its dedication to excellence in engineering and manufacturing has resulted in the development of the Textile Slitting Machine, which has quickly gained recognition as a leading solution for the textile industry.With a global presence and a strong network of distributors and service partners, the company is well-positioned to support garment manufacturers in implementing the Textile Slitting Machine into their production processes. Its commitment to providing comprehensive support, including installation, training, and maintenance services, ensures that clients can maximize the benefits of this innovative technology.In conclusion, the Textile Slitting Machine is revolutionizing the production process for garment manufacturers, offering a high-speed, precision cutting solution that improves efficiency, reduces waste, and enhances the overall quality of garment production. Coupled with the company's reputation for excellence and commitment to customer satisfaction, the machine has quickly become a must-have technology for companies looking to stay ahead in today's competitive market.

High-Quality Paper Slitting and Rewinding Machine for Efficient Production

[Company Name], a leading manufacturer of paper processing machinery, has recently introduced a new generation of Paper Slitting And Rewinding Machine that is set to revolutionize the paper processing industry.The [Company Name] has been at the forefront of innovation in the paper processing industry for over three decades. With a strong focus on research and development, the company has continually introduced cutting-edge machinery that has set new industry standards. The new Paper Slitting And Rewinding Machine is a testament to [Company Name]'s commitment to innovation and excellence.The new Paper Slitting And Rewinding Machine is designed to meet the evolving needs of the paper processing industry. With a focus on efficiency, precision, and automation, the machine offers a range of advanced features that set it apart from traditional models. The machine is capable of slitting and rewinding a wide range of paper materials with high accuracy and speed, making it ideal for large-scale manufacturing operations.One of the key features of the new machine is its advanced control system, which allows for precise adjustment of slitting and rewinding parameters. This level of control ensures that the machine can handle various paper materials, including delicate specialty papers, with ease and accuracy. Furthermore, the machine's automated setup and changeover capabilities minimize downtime and increase overall productivity.The machine also incorporates state-of-the-art safety features to ensure the wellbeing of operators and maintenance personnel. With comprehensive safety interlocks and guarding, the machine adheres to the highest safety standards, providing peace of mind for operators and maintaining a safe working environment.In addition to its advanced features, the new Paper Slitting And Rewinding Machine is designed with sustainability in mind. The machine's energy-efficient design and minimal material waste make it an environmentally friendly choice for paper processing operations. With a focus on reducing environmental impact, [Company Name] continues to lead the way in sustainable manufacturing practices.The new machine has already garnered significant interest from paper manufacturers and converters worldwide. Its ability to improve efficiency, accuracy, and safety while minimizing environmental impact has positioned it as a game-changer in the paper processing industry. [Company Name] has already received orders for the new machine from several key industry players, signaling a strong market demand for its innovative features.In line with [Company Name]'s tradition of providing exceptional after-sales support, the new machine is backed by a comprehensive service and maintenance program. With a global network of service technicians and parts distribution centers, [Company Name] is committed to ensuring that customers can maximize the performance and longevity of their machinery.With the introduction of the new generation Paper Slitting And Rewinding Machine, [Company Name] has once again established itself as a pioneer in the paper processing industry. As the demand for high-quality, efficient, and sustainable paper processing machinery continues to rise, [Company Name] is well-positioned to meet the needs of manufacturers and converters around the world.For more information about the new Paper Slitting And Rewinding Machine and other innovative products from [Company Name], visit their website or contact their sales team directly.

High-Quality Coil Slitting Line for Efficient Metal Processing

Global Machinery Company is proud to announce the launch of their latest innovation, the Coil Slitting Line. The company has been a leading manufacturer of industrial machinery for over 20 years and is known for producing high-quality, reliable equipment for a wide range of industries.The new Coil Slitting Line is designed to meet the needs of metal processing companies that require precision slitting of coils into smaller widths. This state-of-the-art machine is equipped with advanced technology and features that ensure efficient and accurate slitting, making it an essential tool for manufacturers in the metal processing industry.One of the key features of the Coil Slitting Line is its high-speed operation, which allows for fast and efficient processing of coils. This is especially beneficial for companies with high production demands, as it enables them to increase their throughput and reduce turnaround times. Additionally, the machine is equipped with precision slitting blades that can achieve tight tolerances, ensuring the highest level of accuracy in the finished products.The Coil Slitting Line also boasts an intuitive control system that allows for easy operation and adjustment of the slitting parameters. This user-friendly interface makes it simple for operators to set up the machine and make any necessary changes, reducing the time and effort required to switch between different coil sizes.Furthermore, the machine is designed with safety in mind, featuring robust safety guards and emergency stop buttons to protect operators and prevent accidents in the workplace. Global Machinery Company understands the importance of creating a safe working environment, and the Coil Slitting Line reflects their commitment to prioritizing the well-being of their customers and their employees.In addition to its technical capabilities, the Coil Slitting Line is also built to last, with a durable construction and high-quality components that ensure long-term reliability and minimal downtime. This makes it a cost-effective investment for companies looking to improve their production processes and enhance their overall efficiency.The launch of the Coil Slitting Line reaffirms Global Machinery Company's position as a leader in the industrial machinery industry. With a track record of delivering innovative solutions that meet the evolving needs of their customers, the company continues to push the boundaries of what is possible in the world of manufacturing technology.As a global manufacturer, Global Machinery Company is dedicated to providing comprehensive support and service to their customers around the world. The Coil Slitting Line is backed by a team of highly skilled engineers and technical specialists who are committed to ensuring that each customer receives the most value from their investment. Whether it's installation, training, or ongoing maintenance, Global Machinery Company is there every step of the way to support their customers and keep their operations running smoothly.The launch of the Coil Slitting Line represents an exciting new chapter for Global Machinery Company and a significant milestone in their mission to empower manufacturers with the tools they need to succeed. With its cutting-edge technology, precision engineering, and commitment to customer satisfaction, the Coil Slitting Line is set to make a lasting impact on the metal processing industry.

Innovative Pallet Stretch Wrap Machine Enhances Efficiency and Performance

The Pallet Stretch Wrap Machine is a revolutionary piece of equipment that has been designed to streamline the packaging process in warehouses and manufacturing facilities. This innovative machine is capable of efficiently wrapping and securing pallets of goods with stretch film, ensuring that they are properly protected during transit and storage. The machine is equipped with advanced technology that allows for precise wrapping and tension control, resulting in a secure and professional finish every time.The company behind this cutting-edge machine, {}, is a leading provider of packaging and material handling solutions. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering high-quality products that meet the needs of a wide range of industries. By constantly pushing the boundaries of what is possible in packaging and material handling, they have become a trusted partner for businesses looking to improve their efficiency and productivity.One of the key features of the Pallet Stretch Wrap Machine is its ability to automatically adjust the level of tension applied to the stretch film, ensuring that each pallet is wrapped with just the right amount of force. This not only helps to prevent damage to the goods being transported, but also reduces the amount of film used, resulting in cost savings for the user. In addition, the machine is capable of accommodating a variety of pallet sizes and configurations, making it a versatile solution for businesses with diverse packaging needs.The machine is also designed with user-friendliness in mind, featuring intuitive controls and a clear display that allows operators to easily set and monitor the wrapping process. This ensures that even untrained personnel can quickly and effectively use the machine, without the need for extensive training or supervision. As a result, businesses can benefit from increased efficiency and reduced labor costs, all while maintaining a high standard of packaging quality.In addition to its practical benefits, the Pallet Stretch Wrap Machine is also designed with sustainability in mind. By using stretch film to secure pallets, businesses can reduce their reliance on other, less environmentally friendly packaging materials, such as shrink wrap or strapping. This not only helps to minimize the environmental impact of the packaging process, but also aligns with the growing demand for sustainable business practices.Overall, the Pallet Stretch Wrap Machine from {} represents a significant advancement in the field of packaging and material handling. By combining cutting-edge technology with a focus on user-friendliness and sustainability, the machine offers businesses a means to improve their efficiency, reduce costs, and minimize their environmental footprint. With the support of {}, this innovative solution is set to revolutionize the way businesses approach pallet packaging, setting new standards for quality and effectiveness in the process.

Efficient Pallet Wrap Machines for Secure Packaging

Pallet wrapping is an essential process in the logistics and supply chain industry, ensuring that goods are securely packaged and protected during transportation and storage. The use of a pallet wrap machine has greatly improved the efficiency and effectiveness of this process, and one company that has been at the forefront of this technology is {Company Name}.{Company Name} is a leading provider of packaging solutions, specializing in the design and manufacturing of pallet wrapping machines. With a strong focus on innovation and customer satisfaction, the company has continuously developed and improved its products to meet the evolving needs of the industry.The latest offering from {Company Name} is the state-of-the-art Pallet Wrap Machine, which has been designed to streamline the pallet wrapping process and deliver superior performance. This advanced machine is equipped with cutting-edge technology and features that make it a standout choice for businesses looking to enhance their packaging operations.One of the key highlights of the Pallet Wrap Machine is its advanced control system, which allows for precise and customizable wrapping parameters. This ensures that the machine can adapt to a wide range of load sizes and shapes, providing consistent and reliable wrapping results every time. Additionally, the machine is equipped with intelligent sensors that monitor the wrapping process, detecting any abnormalities and making real-time adjustments to optimize the wrapping quality.In addition to its cutting-edge technology, the Pallet Wrap Machine from {Company Name} is designed for ease of use and maintenance. The user-friendly interface and intuitive controls make it simple for operators to set up and operate the machine with minimal training, while the durable construction and high-quality components ensure long-lasting performance with minimal downtime.Furthermore, the Pallet Wrap Machine is designed with efficiency in mind, helping businesses save time and resources. With its high-speed wrapping capabilities and automated features, the machine can significantly increase throughput and productivity, enabling businesses to meet their packaging requirements with ease.{Company Name} takes great pride in its commitment to sustainability and environmental responsibility. As such, the Pallet Wrap Machine has been designed to minimize material waste and energy consumption, making it a greener and more eco-friendly choice for businesses.The Pallet Wrap Machine from {Company Name} has already received positive feedback from early adopters, with users praising its performance, reliability, and user-friendly design. Businesses that have integrated this machine into their operations have reported improved efficiency, reduced packaging costs, and enhanced overall quality of their pallet wrapping process.As the demand for efficient and reliable packaging solutions continues to grow, the Pallet Wrap Machine from {Company Name} is poised to make a significant impact in the industry. With its advanced technology, user-friendly design, and commitment to sustainability, this machine represents the future of pallet wrapping and is set to become an essential asset for businesses looking to optimize their packaging operations.In conclusion, the Pallet Wrap Machine from {Company Name} is a shining example of the company's dedication to innovation and excellence in the packaging industry. With its advanced features, user-friendly design, and commitment to sustainability, this machine is set to revolutionize the way businesses approach pallet wrapping, setting a new standard for efficiency, performance, and reliability.

High-Quality Slitting and Rewinding Equipment for Efficient Production

Slitting And Rewinding Equipment: Revolutionizing the Manufacturing IndustryIn today's fast-paced manufacturing industry, efficiency and precision are key factors in ensuring high-quality products and meeting customer demand. One company at the forefront of this innovation is {}, a leading provider of cutting-edge slitting and rewinding equipment. With their commitment to delivering state-of-the-art technology and unparalleled service, {} has been revolutionizing the manufacturing industry and setting new standards for productivity and reliability.{} has been a trusted name in the industry for over two decades, specializing in the design, development, and manufacturing of a wide range of slitting and rewinding equipment. Their extensive product line includes precision slitting machines, high-speed rewinders, and custom-configured solutions for various applications. Whether it's paper, film, foil, or nonwoven materials, {} has the expertise and resources to provide the ideal solution for their customers' specific needs.One of the key factors that set {} apart from its competitors is its relentless pursuit of innovation. Their team of skilled engineers and technicians are constantly researching and developing new technologies to enhance the performance and functionality of their equipment. This dedication to innovation has resulted in the creation of cutting-edge features such as automatic tension control, precision web guiding systems, and advanced monitoring and inspection capabilities. As a result, {}'s equipment offers unmatched levels of accuracy, efficiency, and reliability, making it the preferred choice for manufacturers around the world.Another critical aspect that sets {} apart is their commitment to customer satisfaction. From the initial consultation to after-sales support, {} provides comprehensive services to ensure that their customers maximize the potential of their equipment. Each solution is tailored to meet the specific requirements of the customer, taking into account factors such as material specifications, production capacity, and space limitations. Furthermore, {}'s team of experts offers training, maintenance, and technical support to ensure that the equipment operates at peak performance, minimizing downtime and maximizing productivity for their customers.In addition to their commitment to innovation and customer satisfaction, {} also places a strong emphasis on quality and reliability. Their state-of-the-art manufacturing facilities adhere to strict quality control standards, ensuring that each piece of equipment is built to the highest industry specifications. Furthermore, {}'s equipment is designed for long-term durability and consistent performance, providing their customers with reliable solutions that stand the test of time.As a result of their dedication to excellence, {} has established a strong reputation as a leader in the slitting and rewinding equipment industry. Their equipment is widely utilized in a diverse range of industries, including packaging, printing, converting, and more. From large-scale operations to small businesses, {}'s solutions have empowered manufacturers to achieve greater efficiency, reduce waste, and improve overall product quality.Looking ahead, {} remains committed to pushing the boundaries of innovation and raising the bar for excellence in the manufacturing industry. With ongoing investments in research and development, as well as a continued focus on customer-centric solutions, {} is poised to remain at the forefront of the industry for years to come.In conclusion, {}'s unwavering dedication to innovation, customer satisfaction, quality, and reliability has established them as a leading provider of slitting and rewinding equipment. As the manufacturing industry continues to evolve, {} is well-positioned to meet the ever-changing needs of their customers, providing them with the tools and support they need to succeed in today's competitive market.

High-Quality Roll Slitter Rewinder for Efficient Material Processing

Roll Slitter Rewinder, a key product offered by a leading manufacturing company, has revolutionized the industry with its advanced features and cutting-edge technology. This precision machine has redefined the process of slitting and rewinding materials, making it more efficient and accurate than ever before. With its state-of-the-art design and unmatched performance, Roll Slitter Rewinder has set a new standard for excellence in the field.The company, which specializes in the production of industrial machinery, has been at the forefront of innovation for over two decades. With a team of highly skilled engineers and technicians, they have consistently delivered superior quality equipment to meet the diverse needs of their clients. The Roll Slitter Rewinder is a testament to their commitment to excellence and their dedication to pushing the boundaries of technological advancement.One of the key features of the Roll Slitter Rewinder is its precision cutting capabilities. With its advanced cutting mechanism, this machine is able to slit materials with unparalleled accuracy, ensuring clean and precise cuts every time. This level of precision is essential for industries that require exact specifications for their materials, such as the packaging and labeling industry. The Roll Slitter Rewinder has proven to be a game changer in these sectors, allowing companies to meet their production needs with unmatched precision and efficiency.In addition to its cutting capabilities, the Roll Slitter Rewinder also boasts a high-speed rewinding function. This allows for seamless and efficient rewinding of materials, reducing downtime and increasing overall productivity. With its customizable settings and user-friendly interface, operators can easily set the machine to meet their specific rewinding requirements, further enhancing the efficiency and versatility of the Roll Slitter Rewinder.Furthermore, the Roll Slitter Rewinder has been designed with durability and longevity in mind. Constructed with high-quality materials and built to withstand the rigors of heavy-duty industrial use, this machine is a reliable and long-lasting investment for any company. Its low maintenance requirements and robust construction ensure that it will continue to deliver exceptional performance for years to come, making it a cost-effective solution for businesses of all sizes.The company behind the Roll Slitter Rewinder takes great pride in providing comprehensive support to their clients. From initial consultation to installation and ongoing maintenance, their team of experts is dedicated to ensuring that every customer receives the highest level of service and satisfaction. With a focus on understanding the unique needs of each client, they work closely with them to deliver tailored solutions that meet and exceed their expectations.As the industry continues to evolve, the Roll Slitter Rewinder remains at the forefront of innovation. The company is constantly researching and developing new technologies to further enhance the capabilities of this machine, ensuring that it remains a market leader in the field of slitting and rewinding equipment. With a relentless commitment to excellence and a passion for continuous improvement, the company is poised to continue setting new standards for performance and reliability in the industry.In conclusion, the Roll Slitter Rewinder is a groundbreaking product that has redefined the industry with its advanced features and cutting-edge technology. Backed by a company known for its unwavering commitment to excellence and customer satisfaction, this precision machine has set a new standard for efficiency, accuracy, and reliability. As the company continues to push the boundaries of innovation, the Roll Slitter Rewinder is poised to remain a leader in the field for years to come.

High-Quality Paper Bag Manufacturing Machine for Efficient Production

The paper bag manufacturing industry is set to receive a significant boost with the introduction of a cutting-edge paper bag manufacturing machine by a leading company in the field. This state-of-the-art machine is designed to revolutionize the production process of paper bags, offering enhanced efficiency, durability, and precision in manufacturing.The company, renowned for its innovative solutions in the packaging industry, has developed this advanced paper bag manufacturing machine in response to the growing demand for eco-friendly and sustainable packaging solutions. With a focus on minimizing environmental impact, the machine is designed to utilize recycled materials and reduce waste generation during the production process.The introduction of this cutting-edge machine signifies a major milestone in the company's commitment to promoting sustainability and environmental stewardship in the packaging industry. By incorporating advanced technology and eco-friendly manufacturing practices, the company aims to set new standards for paper bag production, catering to the evolving needs of businesses and consumers seeking environmentally responsible packaging solutions.Key features of the paper bag manufacturing machine include high-speed production capabilities, precise cutting and folding mechanisms, and customizable options for bag sizes and designs. The machine is equipped with automated controls and quality inspection systems to ensure consistency and accuracy in the production of paper bags, meeting the stringent requirements of the industry and regulatory standards.In addition to its technological advancements, the machine is designed with a focus on user-friendly operation, easy maintenance, and energy efficiency. Its streamlined production process reduces the need for manual intervention, minimizes downtime, and optimizes resource utilization, making it a cost-effective and sustainable solution for paper bag manufacturing.Furthermore, the company's commitment to customer satisfaction is reflected in its comprehensive support services, including installation, training, and technical assistance for clients adopting the new paper bag manufacturing machine. With a dedicated team of experts, the company ensures that customers receive the necessary guidance and resources to maximize the performance and potential of the machine for their specific production needs.The introduction of this innovative paper bag manufacturing machine underscores the company's dedication to advancing the sustainability agenda in the packaging industry. By offering a cutting-edge solution that aligns with the growing demand for eco-friendly packaging options, the company sets itself apart as a leader in driving positive change and innovation in the market.As the global focus on sustainability intensifies, businesses and consumers are increasingly seeking packaging solutions that minimize environmental impact and support responsible consumption. The company, with its new paper bag manufacturing machine, is well-positioned to meet this demand, providing an efficient, reliable, and sustainable production solution for businesses across diverse industries.In conclusion, the introduction of the advanced paper bag manufacturing machine by the company represents a significant step forward in promoting eco-friendly packaging practices and driving innovation in the industry. With its cutting-edge technology, commitment to sustainability, and customer-oriented approach, the company sets a new standard for paper bag production, paving the way for a more sustainable and environmentally responsible future in the packaging industry.

Durable Stretch Film Machine Roll for Packaging Needs

[Company Name] is proud to announce the launch of its latest innovation in the field of packaging machinery - the Stretch Film Machine Roll. This cutting-edge technology is set to revolutionize the packaging industry by offering improved efficiency, durability, and cost-effectiveness.The Stretch Film Machine Roll is designed for use in a wide range of packaging applications, including wrapping of pallets, boxes, and other large or irregularly shaped items. It is capable of delivering a high-quality stretch film which provides a secure and protective wrap around the products being packaged. This ensures that the items are safeguarded during transport and storage, minimizing the risk of damage or loss.One of the key features of the Stretch Film Machine Roll is its versatility. It is suitable for use with a variety of stretch film materials, including polyethylene, PVC, and polypropylene. This means that companies can choose the most appropriate film for their specific packaging needs, whether they require enhanced strength, puncture resistance, or tear resistance.In addition, the Stretch Film Machine Roll is equipped with advanced technology that allows for precise control over the application of the stretch film. This ensures that the wrap is applied evenly and securely, without excessive tension that could potentially damage the products being packaged. The result is a neatly wrapped package that not only looks professional but also provides superior protection.Furthermore, the Stretch Film Machine Roll is designed with durability and longevity in mind. Its robust construction and high-quality components make it capable of withstanding the rigors of heavy-duty industrial use, ensuring reliable performance and minimal downtime. This makes it an ideal investment for companies looking to streamline their packaging processes and reduce maintenance costs.The launch of the Stretch Film Machine Roll is a testament to [Company Name]'s commitment to innovation and excellence in the packaging industry. As a leading manufacturer of packaging machinery, the company has a long-standing reputation for delivering high-quality, reliable, and cost-effective solutions to its customers. With the introduction of the Stretch Film Machine Roll, [Company Name] continues to uphold this tradition and set new standards for packaging technology.In line with its dedication to customer satisfaction, [Company Name] provides comprehensive support for the Stretch Film Machine Roll, including installation, training, and after-sales service. This ensures that customers can maximize the benefits of this innovative technology and achieve optimal results in their packaging operations.The Stretch Film Machine Roll is set to make a significant impact in the packaging industry, offering companies a competitive edge through improved efficiency and cost savings. Whether used in manufacturing facilities, distribution centers, or warehouses, this cutting-edge technology is poised to elevate the standards of packaging practices and deliver tangible benefits to businesses of all sizes.With the launch of the Stretch Film Machine Roll, [Company Name] reaffirms its position as a leader in the packaging machinery market, setting new benchmarks for quality, performance, and innovation. As the industry continues to evolve, [Company Name] remains at the forefront, consistently pushing the boundaries of what is possible in packaging technology.

High-Performance Digital Control Slitting Machine for Jumbo Roll

Digital Control Slitting Machine For Jumbo Roll Revolutionizes Manufacturing ProcessIn an era where efficiency and precision are paramount in the manufacturing industry, the introduction of the state-of-the-art digital control slitting machine for jumbo roll by (brand name removed) is set to revolutionize the production process for a wide range of industries. This innovative technology represents a significant leap forward in the field of industrial machinery, offering enhanced control and flexibility in the slitting of jumbo rolls to meet the diverse needs of modern manufacturing.The digital control slitting machine for jumbo roll is designed to provide a seamless and efficient solution for the precise cutting of large rolls of materials, such as paper, film, foil, and other flexible substrates. With its advanced digital control system, this cutting-edge machine offers unparalleled accuracy and consistency in the slitting process, ensuring that each cut meets the exact specifications required by manufacturers. This level of precision is crucial for industries that rely on jumbo rolls as a primary component in their production line, such as the packaging, printing, and converting sectors.One of the key features of the digital control slitting machine is its ability to handle a wide range of materials with varying thickness and properties. This versatility allows manufacturers to streamline their operations by consolidating their slitting processes into a single, high-performance machine, eliminating the need for multiple machines to accommodate different types of materials. As a result, this innovative technology offers a cost-effective and space-saving solution for businesses looking to optimize their production processes.Furthermore, the digital control system incorporated into the slitting machine offers exceptional flexibility and customization options, allowing manufacturers to tailor the cutting parameters to their specific requirements. This level of control not only enhances the overall quality of the end product but also enables businesses to adapt quickly to changing market demands and production needs. With its user-friendly interface and intuitive programming capabilities, operators can easily adjust the machine settings to achieve the desired cut width, roll diameter, and other critical parameters, ensuring a smooth and efficient production process.The introduction of the digital control slitting machine for jumbo roll by (brand name removed) underscores the company's commitment to innovation and excellence in the field of industrial machinery. With a strong reputation for delivering high-quality and reliable equipment, (brand name removed) has been at the forefront of driving technological advancements in the manufacturing industry. This latest addition to their product lineup further solidifies their position as a trusted partner for businesses seeking cutting-edge solutions to enhance their production capabilities.As manufacturing processes continue to evolve and demand for precision and efficiency grows, the digital control slitting machine for jumbo roll is poised to play a crucial role in helping businesses stay ahead of the curve. By offering a combination of advanced technology, unparalleled precision, and versatility, this innovative machine provides a solid foundation for businesses to optimize their operations and achieve higher levels of productivity and competitiveness in the market.In conclusion, the introduction of the digital control slitting machine for jumbo roll by (brand name removed) marks a significant milestone in the evolution of industrial machinery. With its advanced digital control system, versatility, and user-friendly interface, this cutting-edge technology is set to revolutionize the manufacturing process for a wide range of industries, setting a new standard for precision and efficiency in the slitting of jumbo rolls. As businesses continue to prioritize quality and productivity, the digital control slitting machine emerges as a game-changing solution that offers endless possibilities for the future of manufacturing.