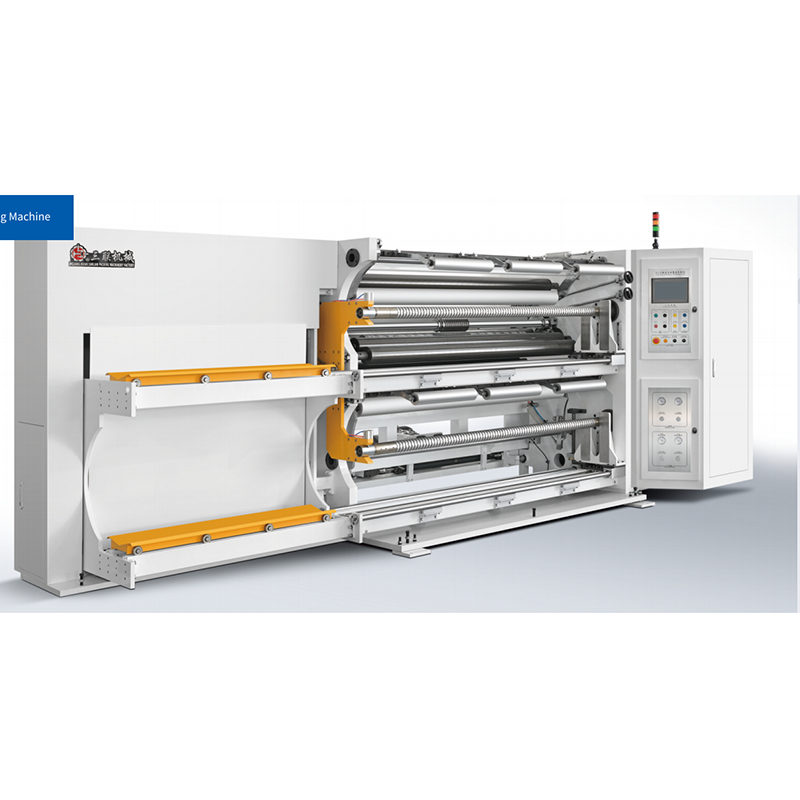

Efficient Non Woven Fabric Roll Cutting Machine for Industrial Use

By:Admin

The latest addition to the company's diverse product line is the Non Woven Fabric Roll Cutting Machine, which is designed to meet the increasing demand for efficient and precise cutting of non-woven fabrics. This cutting-edge machine is set to revolutionize the way non-woven fabrics are handled, offering a range of features and capabilities that are sure to impress industry professionals.

The Non Woven Fabric Roll Cutting Machine is equipped with advanced technology that ensures precise cutting of non-woven fabrics with minimal wastage. This means that manufacturers can maximize the use of their materials, leading to increased efficiency and cost savings. Additionally, the machine is designed to handle a wide range of non-woven fabrics, making it a versatile solution for manufacturers with diverse production requirements.

One of the key advantages of the Non Woven Fabric Roll Cutting Machine is its user-friendly design, which allows for easy operation and maintenance. This feature is particularly important for manufacturers who are looking to streamline their production processes and reduce downtime. With simple controls and intuitive interfaces, the machine can be operated by personnel with varying levels of experience, making it a valuable asset for businesses of all sizes.

In addition to its cutting-edge technology and user-friendly design, the Non Woven Fabric Roll Cutting Machine is also built to last. With durable construction and high-quality components, the machine is capable of withstanding the rigors of industrial production environments, ensuring long-term reliability and performance. This not only gives manufacturers peace of mind but also ensures a strong return on investment.

Ruian Sanlian Packing Machinery Factory has a long-standing reputation for producing high-quality machinery, and the Non Woven Fabric Roll Cutting Machine is no exception. With a commitment to excellence and a focus on customer satisfaction, the company has earned the trust of industry professionals around the world. This latest addition to their product line further solidifies their position as a leading provider of innovative and reliable packaging machinery solutions.

The introduction of the Non Woven Fabric Roll Cutting Machine comes at a time when the demand for non-woven fabrics is on the rise. With applications in a wide range of industries, including healthcare, hygiene, and automotive, the need for efficient and precise cutting solutions has never been greater. This machine is well-positioned to meet this demand, offering manufacturers a valuable tool for optimizing their production processes and meeting the needs of their customers.

As Ruian Sanlian Packing Machinery Factory continues to expand its product line and explore new opportunities in the packaging industry, the company remains committed to its core values of quality, innovation, and customer satisfaction. With a strong track record of success and a dedicated team of professionals, the company is well-equipped to meet the evolving needs of the market and deliver cutting-edge solutions that make a real impact.

In conclusion, the introduction of the Non Woven Fabric Roll Cutting Machine represents a significant milestone for Ruian Sanlian Packing Machinery Factory. With its advanced technology, user-friendly design, and durable construction, this machine is poised to make a lasting impact on the packaging industry. As demand for non-woven fabrics continues to grow, manufacturers can rely on this innovative solution to streamline their production processes and achieve new levels of efficiency and productivity.

Company News & Blog

High-Quality Paper Bag Manufacturing Machine for Efficient Production

The paper bag manufacturing industry is set to receive a significant boost with the introduction of a cutting-edge paper bag manufacturing machine by a leading company in the field. This state-of-the-art machine is designed to revolutionize the production process of paper bags, offering enhanced efficiency, durability, and precision in manufacturing.The company, renowned for its innovative solutions in the packaging industry, has developed this advanced paper bag manufacturing machine in response to the growing demand for eco-friendly and sustainable packaging solutions. With a focus on minimizing environmental impact, the machine is designed to utilize recycled materials and reduce waste generation during the production process.The introduction of this cutting-edge machine signifies a major milestone in the company's commitment to promoting sustainability and environmental stewardship in the packaging industry. By incorporating advanced technology and eco-friendly manufacturing practices, the company aims to set new standards for paper bag production, catering to the evolving needs of businesses and consumers seeking environmentally responsible packaging solutions.Key features of the paper bag manufacturing machine include high-speed production capabilities, precise cutting and folding mechanisms, and customizable options for bag sizes and designs. The machine is equipped with automated controls and quality inspection systems to ensure consistency and accuracy in the production of paper bags, meeting the stringent requirements of the industry and regulatory standards.In addition to its technological advancements, the machine is designed with a focus on user-friendly operation, easy maintenance, and energy efficiency. Its streamlined production process reduces the need for manual intervention, minimizes downtime, and optimizes resource utilization, making it a cost-effective and sustainable solution for paper bag manufacturing.Furthermore, the company's commitment to customer satisfaction is reflected in its comprehensive support services, including installation, training, and technical assistance for clients adopting the new paper bag manufacturing machine. With a dedicated team of experts, the company ensures that customers receive the necessary guidance and resources to maximize the performance and potential of the machine for their specific production needs.The introduction of this innovative paper bag manufacturing machine underscores the company's dedication to advancing the sustainability agenda in the packaging industry. By offering a cutting-edge solution that aligns with the growing demand for eco-friendly packaging options, the company sets itself apart as a leader in driving positive change and innovation in the market.As the global focus on sustainability intensifies, businesses and consumers are increasingly seeking packaging solutions that minimize environmental impact and support responsible consumption. The company, with its new paper bag manufacturing machine, is well-positioned to meet this demand, providing an efficient, reliable, and sustainable production solution for businesses across diverse industries.In conclusion, the introduction of the advanced paper bag manufacturing machine by the company represents a significant step forward in promoting eco-friendly packaging practices and driving innovation in the industry. With its cutting-edge technology, commitment to sustainability, and customer-oriented approach, the company sets a new standard for paper bag production, paving the way for a more sustainable and environmentally responsible future in the packaging industry.

High-Quality 50 Kg Jute Bag Making Machine for Efficient Production

ABC Company, a leading manufacturer of industrial machinery, has recently launched its new 50 Kg Jute Bag Making Machine. This cutting-edge equipment is designed to revolutionize the jute bag manufacturing industry, offering advanced features and high efficiency to meet the growing demand for eco-friendly packaging solutions.The 50 Kg Jute Bag Making Machine is equipped with state-of-the-art technology to ensure precise and consistent production of high-quality jute bags. Its robust construction and advanced engineering make it capable of handling the heavy-duty requirements of jute bag manufacturing. The machine is designed for seamless operation, with user-friendly controls and minimal maintenance requirements, making it an ideal choice for both large-scale industrial jute bag production facilities and smaller enterprises.With the increasing global focus on sustainability and environmental conservation, the demand for jute bags as an eco-friendly alternative to plastic and paper packaging has been steadily growing. Jute, a natural fiber derived from the jute plant, is biodegradable and offers excellent strength and durability, making it an ideal material for packaging applications. The 50 Kg Jute Bag Making Machine by ABC Company is set to meet this demand by providing jute bag manufacturers with a reliable and efficient solution for producing high-quality jute bags at scale.ABC Company has a proven track record in the manufacturing industry, with a strong commitment to innovation and excellence. The company's extensive experience and expertise in designing and producing industrial machinery have enabled it to develop the 50 Kg Jute Bag Making Machine as a cutting-edge solution for jute bag manufacturers. By leveraging advanced technology and engineering, ABC Company aims to set a new standard for jute bag manufacturing equipment, providing its customers with the tools they need to thrive in a competitive market.In addition to its advanced technical specifications, the 50 Kg Jute Bag Making Machine also reflects ABC Company's commitment to sustainability and environmental responsibility. By promoting the use of jute bags as a eco-friendly packaging solution, the company is contributing to the global effort to reduce the reliance on single-use plastics and minimize the environmental impact of packaging materials. With this new machine, jute bag manufacturers can further enhance their sustainability initiatives and meet the growing demand for eco-conscious packaging solutions.The launch of the 50 Kg Jute Bag Making Machine represents a significant milestone for ABC Company, showcasing its dedication to innovation and its mission to provide cutting-edge solutions for the industrial manufacturing sector. As the demand for sustainable packaging solutions continues to rise, ABC Company is well-positioned to lead the way with its high-performance jute bag making equipment. With a focus on quality, efficiency, and sustainability, the company is poised to make a lasting impact in the jute bag manufacturing industry and beyond.In conclusion, the introduction of the 50 Kg Jute Bag Making Machine by ABC Company marks a significant advancement in the jute bag manufacturing industry. With its advanced technology, robust construction, and commitment to sustainability, this machine is set to revolutionize the production of high-quality jute bags, meeting the growing demand for eco-friendly packaging solutions. ABC Company's dedication to innovation and excellence is evident in this cutting-edge equipment, and its launch signifies a new era in the jute bag manufacturing industry.

High-quality Textile Slitting Machine for Efficient Fabric Cutting

Ruian Sanlian Packing Machinery Factory, established in 1996, has been a specialist enterprise in the field of R&D and production of packaging machinery. The company has been dedicated to manufacturing wider size jumbo roll sitter machines/rewinder machines and converting machines. In line with their commitment to innovation and excellence, the company has recently introduced a new Textile Slitting Machine that is set to revolutionize the industry.The Textile Slitting Machine is designed to meet the growing demand for high-quality, precision slitting of textile materials. With its advanced technology and precision engineering, the machine is capable of slitting a wide range of textiles, including fabrics, non-woven materials, and technical textiles. The machine is equipped with state-of-the-art features that ensure superior performance, accuracy, and efficiency.One of the key features of the Textile Slitting Machine is its precision cutting capabilities. The machine is designed to deliver clean, accurate cuts, resulting in a consistent and high-quality end product. This is essential for manufacturers who require precise cutting of textiles for various applications, such as garment production, home furnishings, automotive textiles, and technical textiles.In addition to its cutting precision, the Textile Slitting Machine is also equipped with advanced automation features that enhance its overall efficiency. The machine is designed to operate at high speeds, allowing for increased productivity and throughput. This is crucial for manufacturers looking to optimize their production processes and meet the growing demands of the market.Furthermore, the Textile Slitting Machine is built with user-friendly controls and interfaces, making it easy to operate and maintain. This ensures that operators can quickly and easily set up the machine for different slitting requirements, minimizing downtime and maximizing productivity. The machine's ergonomic design also promotes safety and ease of use for operators, further enhancing its overall appeal to manufacturers.The introduction of the Textile Slitting Machine further strengthens Ruian Sanlian Packing Machinery Factory's position as a leading provider of packaging machinery. The company's commitment to innovation and excellence is reflected in the development of this cutting-edge machine, which is poised to set new industry standards for textile slitting technology.As the global demand for high-quality textiles continues to grow, manufacturers are increasingly seeking advanced machinery that can deliver precision cutting and high productivity. The Textile Slitting Machine from Ruian Sanlian Packing Machinery Factory is well-positioned to meet these needs, offering a reliable and efficient solution for manufacturers looking to enhance their production capabilities.The launch of the Textile Slitting Machine represents a significant milestone for Ruian Sanlian Packing Machinery Factory, further solidifying the company's reputation as a reliable partner for manufacturers in the textile industry. With its advanced technology, precision cutting capabilities, and user-friendly design, the machine is set to make a lasting impact on the industry, driving efficiency and productivity for textile manufacturers around the world.In conclusion, the introduction of the Textile Slitting Machine from Ruian Sanlian Packing Machinery Factory is a testament to the company's dedication to innovation and excellence. With its advanced features and capabilities, the machine is well-equipped to meet the evolving needs of the textile industry, delivering precision cutting, high productivity, and user-friendly operation. As manufacturers continue to seek advanced solutions for their production processes, the Textile Slitting Machine is poised to become an invaluable asset, shaping the future of textile slitting technology.

High-Quality Paper Slitting and Rewinding Machine for Efficient Production

[Company Name], a leading manufacturer of paper processing machinery, has recently introduced a new generation of Paper Slitting And Rewinding Machine that is set to revolutionize the paper processing industry.The [Company Name] has been at the forefront of innovation in the paper processing industry for over three decades. With a strong focus on research and development, the company has continually introduced cutting-edge machinery that has set new industry standards. The new Paper Slitting And Rewinding Machine is a testament to [Company Name]'s commitment to innovation and excellence.The new Paper Slitting And Rewinding Machine is designed to meet the evolving needs of the paper processing industry. With a focus on efficiency, precision, and automation, the machine offers a range of advanced features that set it apart from traditional models. The machine is capable of slitting and rewinding a wide range of paper materials with high accuracy and speed, making it ideal for large-scale manufacturing operations.One of the key features of the new machine is its advanced control system, which allows for precise adjustment of slitting and rewinding parameters. This level of control ensures that the machine can handle various paper materials, including delicate specialty papers, with ease and accuracy. Furthermore, the machine's automated setup and changeover capabilities minimize downtime and increase overall productivity.The machine also incorporates state-of-the-art safety features to ensure the wellbeing of operators and maintenance personnel. With comprehensive safety interlocks and guarding, the machine adheres to the highest safety standards, providing peace of mind for operators and maintaining a safe working environment.In addition to its advanced features, the new Paper Slitting And Rewinding Machine is designed with sustainability in mind. The machine's energy-efficient design and minimal material waste make it an environmentally friendly choice for paper processing operations. With a focus on reducing environmental impact, [Company Name] continues to lead the way in sustainable manufacturing practices.The new machine has already garnered significant interest from paper manufacturers and converters worldwide. Its ability to improve efficiency, accuracy, and safety while minimizing environmental impact has positioned it as a game-changer in the paper processing industry. [Company Name] has already received orders for the new machine from several key industry players, signaling a strong market demand for its innovative features.In line with [Company Name]'s tradition of providing exceptional after-sales support, the new machine is backed by a comprehensive service and maintenance program. With a global network of service technicians and parts distribution centers, [Company Name] is committed to ensuring that customers can maximize the performance and longevity of their machinery.With the introduction of the new generation Paper Slitting And Rewinding Machine, [Company Name] has once again established itself as a pioneer in the paper processing industry. As the demand for high-quality, efficient, and sustainable paper processing machinery continues to rise, [Company Name] is well-positioned to meet the needs of manufacturers and converters around the world.For more information about the new Paper Slitting And Rewinding Machine and other innovative products from [Company Name], visit their website or contact their sales team directly.

High-Quality Slitting Rewinding Services for Your Business

Slitting and Rewinding is an essential process in the manufacturing industry, serving the purpose of cutting large rolls of material into smaller, more manageable rolls. This process is crucial for various industries such as packaging, paper, film, and converting, where precision and accuracy are of utmost importance.In the realm of slitting and rewinding, one company that stands out for its excellent quality and reliable performance is {}. With years of experience in the industry, {} has made a name for itself as a leading provider of slitting and rewinding solutions.Established in [year], {} has consistently delivered top-notch products and services to its customers, catering to a wide range of industries. The company's commitment to innovation and continuous improvement has allowed it to stay ahead of the curve and provide cutting-edge solutions to its clients.{} offers a comprehensive range of slitting and rewinding machinery, designed to meet the specific needs of its customers. Whether it's for custom slitting, precision rewinding, or high-speed production, {} has the expertise and equipment to deliver tailored solutions.One of the key strengths of {} is its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery. This allows the company to produce high-quality slitting and rewinding equipment that meets the highest industry standards.Furthermore, {} takes pride in its team of highly skilled and experienced professionals who are dedicated to providing exceptional service to its customers. The company's technical expertise and industry knowledge enable it to offer reliable advice and support to its clients, ensuring that they get the most out of their slitting and rewinding operations.In addition to its product offerings, {} also provides comprehensive maintenance and support services to its customers. This includes equipment installation, training, and troubleshooting assistance, ensuring that clients can operate their slitting and rewinding machinery with maximum efficiency and effectiveness.Moreover, {} is committed to sustainability and environmental responsibility, incorporating eco-friendly practices into its manufacturing processes. The company places a strong emphasis on reducing waste and energy consumption, while also developing eco-friendly products that align with the principles of sustainability.The success of {} in the slitting and rewinding industry can be attributed to its relentless pursuit of excellence and customer satisfaction. The company's unwavering dedication to quality, innovation, and service has earned it a sterling reputation in the market, making it the go-to choice for slitting and rewinding solutions.Looking to the future, {} continues to strive for growth and development, exploring new technologies and opportunities to further enhance its product offerings and services. Through its commitment to excellence and customer-centric approach, {} is well-positioned to remain a leader in the slitting and rewinding industry for years to come.In conclusion, slitting and rewinding is a critical process in various industries, and {} is a company that has consistently delivered top-notch solutions to meet the needs of its customers. With its focus on quality, innovation, and customer satisfaction, {} has established itself as a trusted and reliable partner in the slitting and rewinding industry.

Innovative Pallet Stretch Wrap Machine Enhances Efficiency and Performance

The Pallet Stretch Wrap Machine is a revolutionary piece of equipment that has been designed to streamline the packaging process in warehouses and manufacturing facilities. This innovative machine is capable of efficiently wrapping and securing pallets of goods with stretch film, ensuring that they are properly protected during transit and storage. The machine is equipped with advanced technology that allows for precise wrapping and tension control, resulting in a secure and professional finish every time.The company behind this cutting-edge machine, {}, is a leading provider of packaging and material handling solutions. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering high-quality products that meet the needs of a wide range of industries. By constantly pushing the boundaries of what is possible in packaging and material handling, they have become a trusted partner for businesses looking to improve their efficiency and productivity.One of the key features of the Pallet Stretch Wrap Machine is its ability to automatically adjust the level of tension applied to the stretch film, ensuring that each pallet is wrapped with just the right amount of force. This not only helps to prevent damage to the goods being transported, but also reduces the amount of film used, resulting in cost savings for the user. In addition, the machine is capable of accommodating a variety of pallet sizes and configurations, making it a versatile solution for businesses with diverse packaging needs.The machine is also designed with user-friendliness in mind, featuring intuitive controls and a clear display that allows operators to easily set and monitor the wrapping process. This ensures that even untrained personnel can quickly and effectively use the machine, without the need for extensive training or supervision. As a result, businesses can benefit from increased efficiency and reduced labor costs, all while maintaining a high standard of packaging quality.In addition to its practical benefits, the Pallet Stretch Wrap Machine is also designed with sustainability in mind. By using stretch film to secure pallets, businesses can reduce their reliance on other, less environmentally friendly packaging materials, such as shrink wrap or strapping. This not only helps to minimize the environmental impact of the packaging process, but also aligns with the growing demand for sustainable business practices.Overall, the Pallet Stretch Wrap Machine from {} represents a significant advancement in the field of packaging and material handling. By combining cutting-edge technology with a focus on user-friendliness and sustainability, the machine offers businesses a means to improve their efficiency, reduce costs, and minimize their environmental footprint. With the support of {}, this innovative solution is set to revolutionize the way businesses approach pallet packaging, setting new standards for quality and effectiveness in the process.

Top 10 Polythene Making Machines on the Market

The global demand for polythene has been growing rapidly in recent years, driven by its wide range of applications in packaging, agriculture, construction, and other industries. As a result, manufacturers are constantly seeking to enhance their production capabilities to meet the increasing market demand. In response to this trend, {Company Name}, a leading provider of industrial machinery, has introduced a state-of-the-art Polythene Making Machine, designed to offer high efficiency and precision in polythene production.{Company Name} has been a prominent player in the industrial machinery market for several decades, specializing in the design and manufacturing of advanced production equipment. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering high-quality solutions tailored to the specific needs of its clients. The introduction of the Polythene Making Machine underscores {Company Name}'s commitment to advancing the capabilities of the manufacturing industry and supporting the business growth of its customers.The newly released Polythene Making Machine is equipped with the latest technologies, including advanced control systems and precision components, to ensure optimal performance and product quality. The machine is capable of producing a wide range of polythene products, such as films, bags, and sheets, with varying thickness and specifications. Its versatile design allows for seamless integration into existing production lines, providing manufacturers with greater flexibility and efficiency in their operations.One of the key features of the Polythene Making Machine is its high production capacity, enabling manufacturers to meet large-scale demands without compromising on quality. The machine is engineered to deliver consistent and reliable output, minimizing downtime and optimizing resource utilization. In addition, it is equipped with automated controls and monitoring systems, allowing for real-time adjustments and preventive maintenance to ensure uninterrupted operation.{Company Name} has also placed a strong emphasis on the sustainability and environmental impact of the Polythene Making Machine. The machine is designed to minimize energy consumption and waste generation, aligning with the industry's growing focus on eco-friendly manufacturing practices. By utilizing efficient production processes and materials, the machine supports the sustainable production of polythene products, meeting the evolving needs of environmentally conscious consumers and businesses.Furthermore, {Company Name} provides comprehensive technical support and services for the Polythene Making Machine, including installation, training, and maintenance. The company's team of engineers and technicians are dedicated to assisting clients in optimizing their production processes and maximizing the performance of the machine. With a global network of service centers and support facilities, {Company Name} ensures that its customers receive prompt and reliable assistance whenever necessary.The introduction of the Polythene Making Machine represents a significant milestone for {Company Name} and the manufacturing industry as a whole. By offering a technologically advanced and sustainable solution for polythene production, the company is poised to empower manufacturers with the tools they need to meet the demands of today's market and achieve long-term success.As the global demand for polythene continues to rise, {Company Name} remains at the forefront of providing cutting-edge solutions that drive the industry forward. With its commitment to innovation, quality, and customer satisfaction, the company is well-positioned to play a key role in shaping the future of polythene manufacturing and supporting the growth of businesses worldwide.

Efficient Thermal Transfer Ribbon Slitting Machine: Enhance Your Production

Ruian Sanlian Packing Machinery Factory, a specialist enterprise established in 1996, has announced the launch of a new Thermal Transfer Ribbon Slitting Machine. This innovative machine is set to revolutionize the packaging industry with its advanced features and high efficiency.The Thermal Transfer Ribbon Slitting Machine is designed to cater to the growing demand for precision in slitting and rewinding thermal transfer ribbons. With its cutting-edge technology, this machine is capable of delivering superior performance and accuracy, making it the perfect solution for businesses looking to enhance their production processes.The machine is equipped with state-of-the-art slitting and rewinding mechanisms that ensure smooth and precise cutting of thermal transfer ribbons, resulting in high-quality finished products. It is also designed to handle wider size jumbo rolls, making it suitable for a variety of applications in the packaging industry.As a leader in the packaging machinery industry, Ruian Sanlian Packing Machinery Factory has a proven track record of delivering reliable and high-quality products to its customers. The new Thermal Transfer Ribbon Slitting Machine is a testament to the company's commitment to innovation and excellence.In addition to the Thermal Transfer Ribbon Slitting Machine, Ruian Sanlian Packing Machinery Factory specializes in manufacturing a wide range of jumbo roll slitter machines, rewinder machines, and converting machines. These products are designed to meet the diverse needs of businesses in the packaging industry, catering to various materials and production requirements.The company's dedication to research and development has enabled it to stay ahead of the competition, constantly introducing new and improved products to meet the evolving needs of the market. With a focus on efficiency, precision, and reliability, Ruian Sanlian Packing Machinery Factory has established itself as a trusted partner for businesses seeking high-quality packaging machinery solutions.The launch of the Thermal Transfer Ribbon Slitting Machine is a significant milestone for Ruian Sanlian Packing Machinery Factory, further solidifying its position as a leading provider of innovative packaging machinery. The machine's advanced features and capabilities are expected to set a new standard in the industry, offering businesses a competitive edge in their production processes.As the demand for high-quality packaging solutions continues to grow, Ruian Sanlian Packing Machinery Factory remains committed to delivering top-notch products that meet the highest standards of performance and reliability. The company's extensive experience and expertise in the field of packaging machinery make it a sought-after partner for businesses looking to enhance their operations.With its focus on innovation and customer satisfaction, Ruian Sanlian Packing Machinery Factory is well-positioned to drive the future of the packaging industry. The launch of the Thermal Transfer Ribbon Slitting Machine is a clear reflection of the company's dedication to pushing the boundaries of technology and delivering unparalleled value to its customers.In conclusion, the new Thermal Transfer Ribbon Slitting Machine from Ruian Sanlian Packing Machinery Factory is set to make a significant impact in the packaging industry. With its cutting-edge technology and unparalleled performance, this machine is poised to become an essential tool for businesses looking to elevate their production processes. Ruian Sanlian Packing Machinery Factory's commitment to excellence and innovation ensures that the company will continue to be a driving force in the industry, offering top-of-the-line solutions to meet the evolving needs of its customers.

Top Automatic Pallet Shrink Wrap Machine: A Complete Guide

Ruian Sanlian Packing Machinery Factory has recently launched its latest Automatic Pallet Shrink Wrap Machine, offering a more efficient and cost-effective solution for businesses in need of pallet packaging. With over two decades of experience in the industry, the company has established itself as a leading specialist enterprise in the manufacturing of packaging machinery.Established in 1996, Ruian Sanlian Packing Machinery Factory has been dedicated to research, development, and production of high-quality packaging machinery. The company has garnered a reputation for its expertise in manufacturing wider size jumbo roll sitter machines/rewinder machines and converting machines, catering to the diverse needs of the packaging industry.The newly launched Automatic Pallet Shrink Wrap Machine is set to meet the growing demand for advanced pallet packaging solutions. This state-of-the-art machine is designed to streamline the pallet packaging process, offering automation and efficiency to businesses of all sizes. With its innovative features and durable construction, the machine is poised to set a new standard in pallet packaging technology.The Automatic Pallet Shrink Wrap Machine offers a range of benefits for businesses looking to optimize their packaging operations. By automating the shrink wrapping process, the machine reduces the need for manual labor, saving time and labor costs for businesses. Additionally, the machine ensures a consistent and secure wrapping of pallets, minimizing the risk of damage during transportation and storage.The machine is equipped with cutting-edge technology to ensure precision and reliability in pallet packaging. Its user-friendly interface allows for easy operation, making it accessible for businesses with varying levels of technical expertise. With customizable settings and adjustable wrapping parameters, the machine can accommodate a wide range of pallet sizes and packaging requirements.In addition to its efficiency and functionality, the Automatic Pallet Shrink Wrap Machine is designed with durability and longevity in mind. Built with high-quality materials and components, the machine is capable of withstanding the rigors of continuous use in industrial settings. Its robust construction ensures minimal maintenance requirements, further contributing to cost savings for businesses.Ruian Sanlian Packing Machinery Factory has also emphasized the importance of sustainability in the design of the Automatic Pallet Shrink Wrap Machine. By optimizing the use of materials and energy, the machine offers an eco-friendly packaging solution for businesses. This aligns with the company's commitment to environmental responsibility and its efforts to contribute to sustainable practices in the packaging industry.As the global demand for efficient and sustainable packaging solutions continues to rise, the launch of the Automatic Pallet Shrink Wrap Machine underscores Ruian Sanlian Packing Machinery Factory's dedication to innovation and meeting the evolving needs of the market. The company's extensive experience and expertise in packaging machinery position it as a trusted provider of advanced solutions for businesses seeking to enhance their packaging operations.With its latest offering, Ruian Sanlian Packing Machinery Factory is poised to make a significant impact in the pallet packaging sector, setting a new benchmark for performance, reliability, and sustainability. The Automatic Pallet Shrink Wrap Machine represents a culmination of the company's decades-long commitment to excellence in packaging machinery, and it is expected to resonate with businesses seeking to optimize their pallet packaging processes.In conclusion, the launch of the Automatic Pallet Shrink Wrap Machine by Ruian Sanlian Packing Machinery Factory is a testament to the company's leadership in the packaging machinery industry. With its advanced features, efficiency, and sustainability, the machine is set to address the needs of businesses looking to enhance their pallet packaging operations. As the company continues to pave the way for innovative solutions, it stands to make a lasting impact on the future of packaging technology.

Benefits of a Manual Stretch Wrap Machine for Packaging and Shipping

FOR IMMEDIATE RELEASENew Manual Stretch Wrap Machine Revolutionizes Packaging Process[City, State] – [Company Name], a leading provider of innovative packaging solutions, is proud to announce the launch of a new Manual Stretch Wrap Machine that is set to revolutionize the way companies package their products. This innovative machine has been designed to simplify and streamline the packaging process, ultimately leading to increased efficiency and cost savings for businesses of all sizes.The Manual Stretch Wrap Machine features state-of-the-art technology and a user-friendly design, making it easy for operators to pack and wrap pallets with precision and speed. It is ideal for a wide range of industries, including manufacturing, distribution, and logistics, and can accommodate a variety of load sizes and shapes."We are thrilled to introduce our new Manual Stretch Wrap Machine to the market," said [Spokesperson], [Title] of [Company Name]. "We have been working tirelessly to develop a solution that addresses the pain points of traditional packaging methods and are confident that this new machine will exceed the expectations of our customers."The Manual Stretch Wrap Machine is designed to provide a secure and tamper-evident wrap, ensuring that products are protected during transit and storage. Its ergonomic design minimizes operator fatigue and strain, allowing for longer and more productive packaging runs. Additionally, the machine's intuitive controls and adjustable tension settings provide flexibility and precision in wrapping, resulting in a professional and uniform finish every time.In addition to its advanced features, the Manual Stretch Wrap Machine is also eco-friendly, offering a sustainable packaging solution for businesses looking to reduce their environmental impact. By using less material and minimizing waste, companies can lower their carbon footprint while maintaining the integrity of their products.As part of [Company Name]'s commitment to customer satisfaction, the Manual Stretch Wrap Machine is backed by a comprehensive support and service program. The company's team of packaging experts is available to provide training, technical assistance, and ongoing maintenance to ensure that the machine operates at peak performance."[Company Name] has been a trusted partner for businesses seeking packaging solutions that are both innovative and reliable," added [Spokesperson]. "With the introduction of the Manual Stretch Wrap Machine, we are further solidifying our position as a leader in the industry and reinforcing our dedication to meeting the evolving needs of our customers."For more information about the Manual Stretch Wrap Machine and other packaging solutions offered by [Company Name], please visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading provider of innovative packaging solutions for businesses across a wide range of industries. With a focus on quality, efficiency, and sustainability, the company offers a comprehensive portfolio of packaging products and services designed to meet the unique needs of its customers. [Company Name] is committed to delivering exceptional value and customer satisfaction through its dedication to excellence and continuous innovation.Media Contact:[Name][Title][Company Name][Phone Number][Email Address]